First shot = initial repair = entry point in the strategy

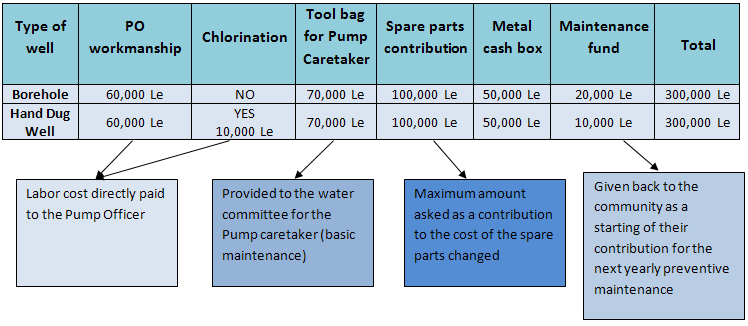

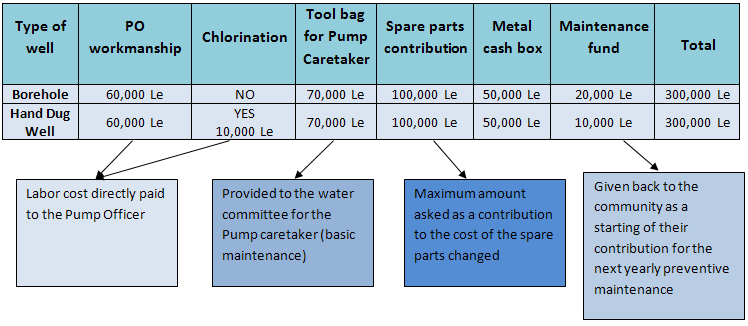

Once the water committee is trained, it is left to the community organizing itself to gather the conditions requested for an Inter Aide intervention on their pump. These conditions are the following: contribution of Le 300,000, fencing of the well[1] and cleaning of its environment: as some pumps are broken down beyond the community’s ability to pay the full cost, Inter Aide only subsidizes this first intervention.

Depending on the work to be done, this operation lasts on average one full day and aims at repairing and upgrading the hand pump (replacement of any galvanized parts by stainless ones). The following steps are respected:

- Preparation at the office of the spare parts needed according to the diagnose form. Spare parts delivery on site

- Introduction meeting to remind the community about the purpose of this visit

- Repair of the pump by the Pump Officer under the supervision of Inter Aide.

- Receipt of intervention filling: for any intervention, the technical team must fill it with the list of the spare parts changed, the amount of money collected and the purpose of the money. This receipt is filled in 2 copies: one for the office and the other one for the water committee. Final meeting with water committee and community members.

- Delivery of tools and documentation: after the first shot, the pump caretaker receives the tools provided by Inter Aide for his basic maintenance work. A metal cash box is also provided to the committee to secure the money collected.

[1] The fencing can be locally made with sticks at first. Once the first shot is done, Inter Aideproposes to the communities a strategy to build a concrete fence: if the community provides mud blocks and 2 bags of cement then the program provides also 2 bags of cement. With 4 bags, the village has enough cement to seal the blocks and to plaster the fence all around to reinforce it.

Regular repairs :

The cost of the workmanship for the Pump Officer depends on the type of repair:

- Minor repair is an intervention focused only on the hand pump head assembly (changing of bearings, chain, etc.) The Pump Officer does not need to dismantle the entire system. In this case his workmanship is Le 40,000.

- Major repair is an intervention where the entire hand pump has to be dismantled (changing of cylinder valve, connecting rod disconnection, etc.). In this case the Pump Officer workmanship is Le 60,000.

Preventive maintenance :

Once the first repair has been done, the next main challenge is to encourage the communities to enter in a regular maintenance scheme of their pump. To ensure the sustainability of their facility and avoid major and expensive repairs, a yearly preventive maintenance of the pump by their Pump Officer in charge is highly recommended.

A preventive maintenance consists in dismantling the entire pump in order to achieve a complete diagnosis of the system. Once a year, the Pump Officer books a date for this intervention with the committee. All the parts are checked, cleaned, greased and replaced if necessary in order to ensure a proper functioning until the next maintenance the year after.

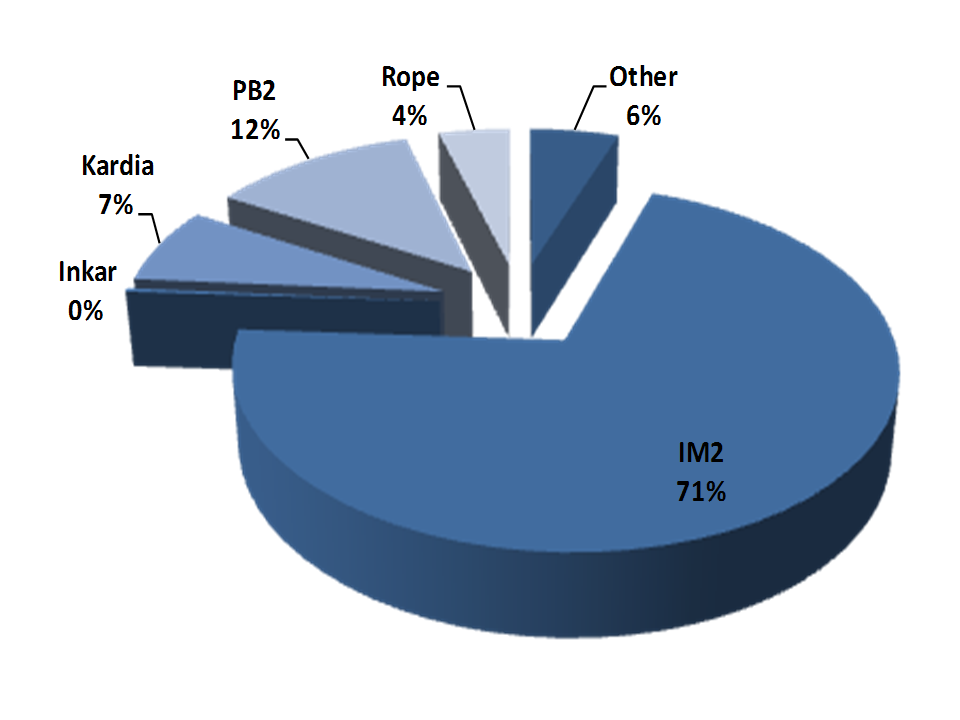

Hand pump made in India: galvanized or stainless type. In Sierra Leone, this pump is available in most of the suppliers at a reasonable cost for stainless type (around 2.900.000 SLL) and offers a good quality for its price. A regular maintenance is compulsory to ensure the sustainability and avoid major breakdown. The installation process is also really important and has to be done properly (iron rods lengths, cylinder position from the bottom, hand pump stand straight…).

Hand pump made in India: galvanized or stainless type. In Sierra Leone, this pump is available in most of the suppliers at a reasonable cost for stainless type (around 2.900.000 SLL) and offers a good quality for its price. A regular maintenance is compulsory to ensure the sustainability and avoid major breakdown. The installation process is also really important and has to be done properly (iron rods lengths, cylinder position from the bottom, hand pump stand straight…).