Category Archives: The hand pump maintenance approach

What is an Area Mechanic ?

Area Mechanics or Hand Pump technicians are able to repair or diagnose hand pump within their catchment area. One hand pump technician has from 50 to 100 hand pumps to cover, mostly Afridev ones (some districts are also equipped with Malda pumps).

They can intervene in case of breakdown but they are also proposing contracts for servicing to help the community for preventive maintenance (3 to 4 visits a year).

They can intervene in case of breakdown but they are also proposing contracts for servicing to help the community for preventive maintenance (3 to 4 visits a year).

They are officially recognized by the government and the Ministry of Agriculture, Irrigation and Water Development.

Area Mechanics are identified and then trained by Inter Aide or BASEDA / TIMMS by looking for skilled persons among the communities and according also to the recommendations of the Water department and District Council. This is also taking into account the needs in the area targeted : number of pumps that one person can supervised, according to distances and accessibility, avoiding also competitions between AMs so that each how them can gain benefits from this activity.

In 2016, there are 388 AMs in Malawi who have been trained by Inter Aide – BASEDA – TIMMS, see details on the map.

The complete list of AMs (and partners shops) for 2016 is available here: BROCHURE List of all AM SHOPS

What is a partner shop ?

It can be any shop which is clearly identified by the communities, frequented, which is well located in a trading center and for which his owner is ready to support the communities by facilitating access to hand pump spare parts.

Generally it can be hardware shops, groceries, even tailors…

They agree to collaborate with Inter Aide, BASEDA, TIMMS, and since 2012 with RUWASO who are linking them with main suppliers of Afridev and Malda pumps located in main cities like Lilongwe and Blantyre, and they are reselling (with some profit – around 20% for the fast wearing parts) to any water point users, thus facilitating access even for remote villages.

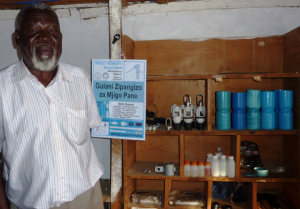

M. Guande, shop owner, in front of the shelf that displays the spare parts to the customers

Shops owners are selected also according to their capacities to manage and develop such business. Selection is made with the advises of District Councils and Water Departments.

Then, they are trained to have the basic knowledge of the use of spare parts, bust most of all to well manage this activity so that water point users are well oriented and can always find the parts they are looking for.

Sign boards used to identify spare parts resellers

In 2016, there are 150 spare parts retailers in Malawi who have been trained by Inter Aide – BASEDA – TIMMS, see details on the map.

The complete list of partners shops (and AMs) for 2016 is available here: BROCHURE List of all AM SHOPS

Few explanations on Afridev and Malda hand pumps

Afridev and Malda pumps both started ”life” in Malawi in the early 80’s.

Focus on the development of Afridev shifted then to Kenya in 1983 ; and the Malda is the ”direct action” version of the Afridev pump developed in Malawi – MALawi Direct Action Pump : in 1994, UNICEF placed an initial order of 100 MALDA produced locally and installed in the project areas of Inter Aide and Concern Universal.

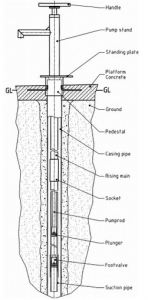

Both of them are piston pumps.

Both of them are piston pumps.

” The piston is fitted with a non-return valve (the piston valve) and slides vertically up and down within a cylinder that is also fitted with a non-return valve (the foot valve). Raising and lowering the handle of the pump causes vertical movement of pump rods that are connected to the piston. When the piston moves upwards, the piston valve closes and a vacuum is created below it, causing water to be drawn into the cylinder through the foot valve, which opens. Simultaneously, water above the piston, held up by the closed piston valve, is displaced upwards. In a simple suction pump it emerges through the delivery outlet. When the piston moves downwards, the foot valve closes, preventing backflow, and the piston valve opens, allowing the piston to move down through the water in the cylinder. ”

source Water Aid : http://www.wateraid.org/~/media/Publications/Handpumps.pdf

These pumps have been designed so that it could be maintained by users (VLOM pumps -Village Level Operation and Maintenance) and could be manufactured locally.

The Afridev, in comparison to another popular hand pump – the India Mark II* -, can be considered as less robust, as wearing parts need to be change regularly (yearly), but the repair can be done more easily:

The Afridev, in comparison to another popular hand pump – the India Mark II* -, can be considered as less robust, as wearing parts need to be change regularly (yearly), but the repair can be done more easily:

*India Mark II are not VLOM

- need few tools

- the piston can be removed from the cylinder without dismantling the rising main. The foot valve is retractable with a fishing tool, meaning less risks of rods falling down and losing the borehole.

It is designed to lift water from a depth no greater than 45 metres.

More information here:

www.rural-water-supply.net/en/implementation/public-domain-handpumps/afridev

rural-water-supply.net/_ressources/documents/default/286.pdf

or here

akvopedia.org/wiki/Afridev_pump

The MALDA pump is a direct action pump, i.e. operating without the help of leverage, linkages and bearings, and depend on the strength of the operator pumping to lift the column of water.

The maximum recommended lift is 15 m.

More information here:

www.rural-water-supply.net/en/implementation/public-domain-handpumps/malda-pump

www.rural-water-supply.net/_ressources/documents/default/MALDA_Installation-Manual_Ed-2003.pdf

or here

akvopedia.org/wiki/Malda_pump

To go further: www.rural-water-supply.net/en/resources/details/475

Hand pumps maintenance : a thematic worth to be shared

In December 2012 an internal workshop and exchange was held by Inter Aide between Program managers from Ethiopia, Sierra Leone and Malawi. It was the opportunity to learn and exchange from each other on methods and tools related to ”maintenance programs” and especially on the maintenance of hand pumps.

The 1st week was spent in Ethiopia with Yembeh, who came from Sierra Leone to explain to his Ethiopian colleagues the working principles of India Mark pumps. Indeed, the context where Inter Aide is working in Ethiopia allows the construction of gravity fed networks, whereas in Sierra Leone, the team is constructing and equipping hand dug wells. However, in the lowlands of Ethiopia, hand pumps are more common and the team wanted to get more experience on it in order to integrate such systems into a maintenance approach.

Yembeh (right) explaining India Mark pumps to his colleagues from Ethiopia

In the meantime, Yembeh had the opportunity to learn more about gravity schemes thanks to Asrat, WASH coordinator in Ethiopia.

Then the 2nd week Yembeh ; Akalu – WaSH program manager from Ethiopia ; Gedewon – WaSH Coordinator of our partner RCBDI, has been introduced to the networks of Area Mechanics and spare parts retailers in Malawi by BASEDA + TIMMS represented by its coordinator Teddy, and Laurent, Inter Aide’s Program manager. It was the opportunity for them to discover a large hand pump maintenance scale project covering a lot of communities.

In the meantime, visiting the project in Phalombe, the Ethiopian team provided also some advises for rehabilitation of gravity schemes.

The following link summarizes the exchange done during this workshop

www.interaide.org/pratiques/content/summary-exchanges-between-inter-aides-program-managers-ethiopia-malawi-and-sierra-leone